THE DECARBONIZATION JOURNEY: HOW TO PREPARE YOUR BUILDING FOR ELECTRIFICATION

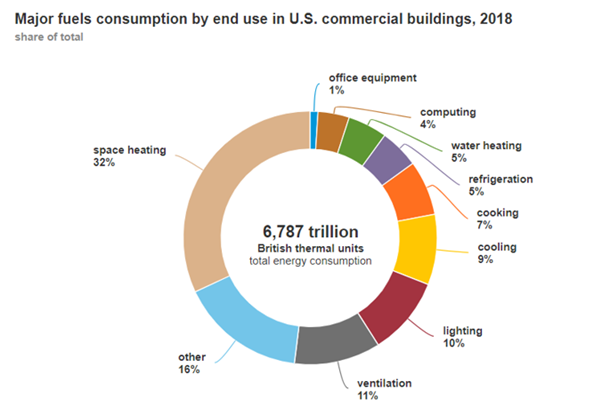

Did you know that more than one-third of the energy used by commercial buildings in the US goes toward heating spaces and providing hot water?

As regulations and standards continue to drive decarbonization, building owners and operators often view moving to technologies such as heat pumps or on-site renewables as the immediate solution. However, before simply replacing one energy source with another, it pays to evaluate a building’s energy consumption holistically first.

Taking a phased approach to decarbonization — and delivering energy efficiencies before making major capital investments in HVAC electrification — can significantly reduce upfront and operating costs over time.

REDUCING BUILDING LOADS

A phased decarbonization strategy should begin with a comprehensive facility assessment, starting with the building envelope, the exterior and structural elements that impact energy performance. While this can vary widely from one building to the next, enhancing the building envelope can significantly reduce energy consumption, emissions, and costs.

Upgrading windows, insulation, and sealing leaks in walls, roofs, windows, doors, and around penetration lowers HVAC loads, reducing energy use for heating and cooling and the corresponding costs.

Next, examine internal electrical and mechanical loads. Energy-efficient lighting and plug load controls can reduce electricity loads within a building, enabling significantly reduced power usage.

Turning our attention to HVAC, ventilation remains one of the greatest opportunities for improving efficiency. Combining modern ventilation technologies and the latest design methodology can minimize the amount of outside air that needs to be brought in for cooling, dehumidification, or heating. This immediately impacts electricity use and costs. For instance, Daikin’s Sorbent Ventilation Technology can reduce the need for outside ventilation by 40–60% and cut HVAC-related operating expenses (OPEX) by as much as 25%.

Similarly, heat recovery systems can decrease building loads, emissions, and OPEX by transferring heat from areas that require cooling, like offices and server rooms, to spaces that need heating or hot water.

Reducing building loads in this way can improve energy efficiency and minimize the size of heating and cooling equipment required, lowering upfront costs.

Using a single system for heating and cooling

Another area where building operators can make significant strides forward is by consolidating HVAC systems.

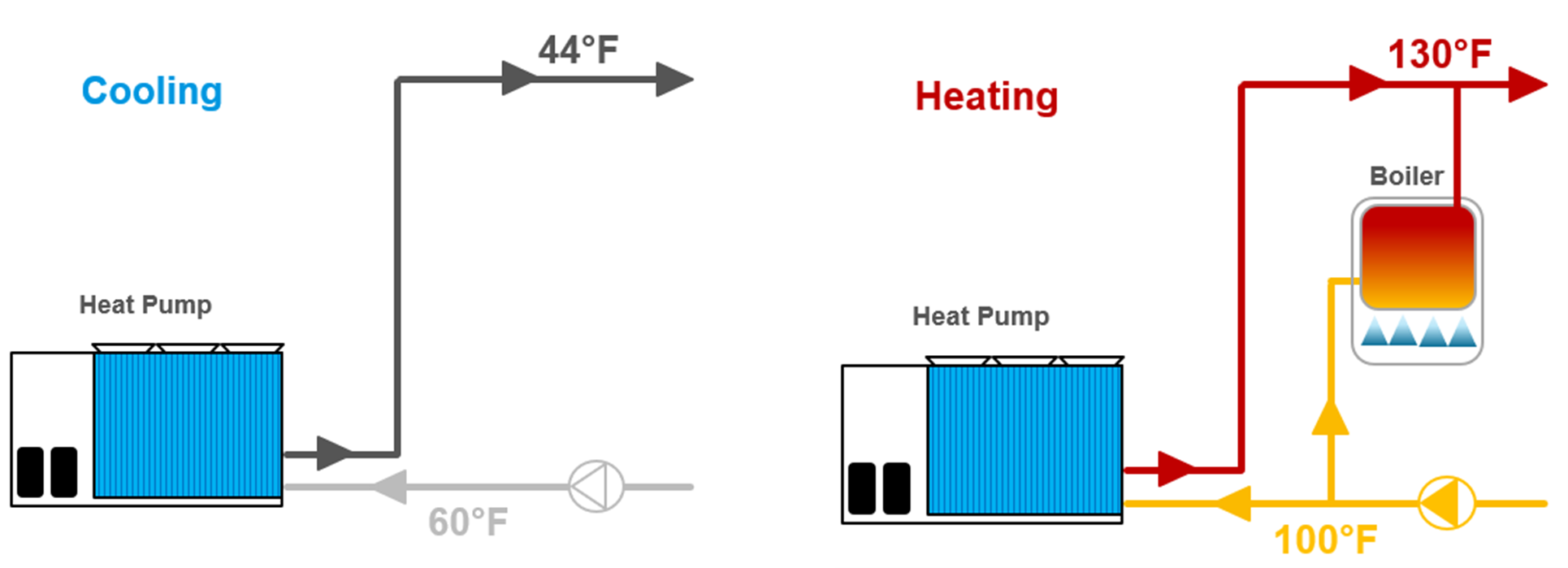

Traditionally, systems for heating and cooling have been separate; boiler and chiller plants each had dedicated infrastructure, and there are typically few, if any, synergies between them.

Heat pumps combine heating and cooling in a single system, reducing energy use and physical footprint while also enabling energy sharing and recovery compared to separate systems. However, a potential trade-off is the need for additional electrical capacity, particularly in colder climates where supplemental heating may be required.

For rooftop heat pump systems, this challenge can be addressed with configurable electrical connections, which simplify capacity upgrades by enabling separate circuits for the heat pump and supplemental electric heat. In retrofits, the heat pump can reuse the existing electrical circuit of the rooftop unit it replaces, while the addition of a smaller circuit accommodates supplemental heat.

Another approach is reusing existing heating systems. For example, a natural gas hot water boiler may be used to supplement the heat pump during extreme conditions.

Source: Daikin

MAKING THE RIGHT SYSTEM CHOICES

After identifying a building’s HVAC optimization potential, it’s important to address several often-overlooked factors.

One of these is handling load variation. Minimizing short-cycling, frequent on-off switching, is essential for extending equipment life. Combining a heat pump with energy storage can help manage peak loads and reduce short cycling.

The application of supplemental heat is also a strategy for “right-sizing” heat pumps. In other words, sizing the heat pump for 80-90% of the heating operating hours, met by supplemental heat. This approach allows for the use of a smaller capacity heat pump that modulates more effectively at part and low loads.

To optimize part-load operation, modern heat pumps feature inverter compressors and variable-speed fans that adjust motor speeds to maintain continuous, efficient operation. This boosts efficiency and lowers energy use and operating costs. Daikin’s inverter compressors, for example, canreduce energy consumption by30%compared to traditional fixed-speed systems.

The choice of refrigerant is another decision that requires careful consideration. Using low global warming potential (GWP) refrigerants can substantially reduce emissions and costs, but selecting the most suitable refrigerant is dependent on the building’s requirements. Choosing the refrigerant withthe lowest GWP does not always equate to the highest efficiencies and lowest emissions.

Finally, despite best efforts to improve building sustainability and energy efficiency, some buildings will still require supplemental heat. While using electric resistance backup systems has been a common solution, these often rely heavily on fossil-fuel-intensive electricity from the grid. Alternatives, such as energy storage or natural gas systems, can offer more cost-effective and lower-emission options.

A PHASED APPROACH PAYS DIVIDENDS

Each decarbonization journey is unique, and there is no cookie-cutter solution for every scenario. Similarly, making large upfront investments in electrification technology does not always guarantee the best results.

A phased strategy is likely to be more effective, starting with a thorough assessment of a building’s energy use to ensure that the envelope and existing systems are optimized before adding new technology.

Proceeding step by step enables a ‘pay as you go’ approach to investments, spreading costs over time. It also allows building owners, system designers, and technology suppliers to make sustainable, future-proof decisions, ensuring long-term environmental and commercial viability.